From Specification to Integration

Turning

Turning operations are carried out on general-purpose or customized lathes, typically for components requiring medium-level tolerances.

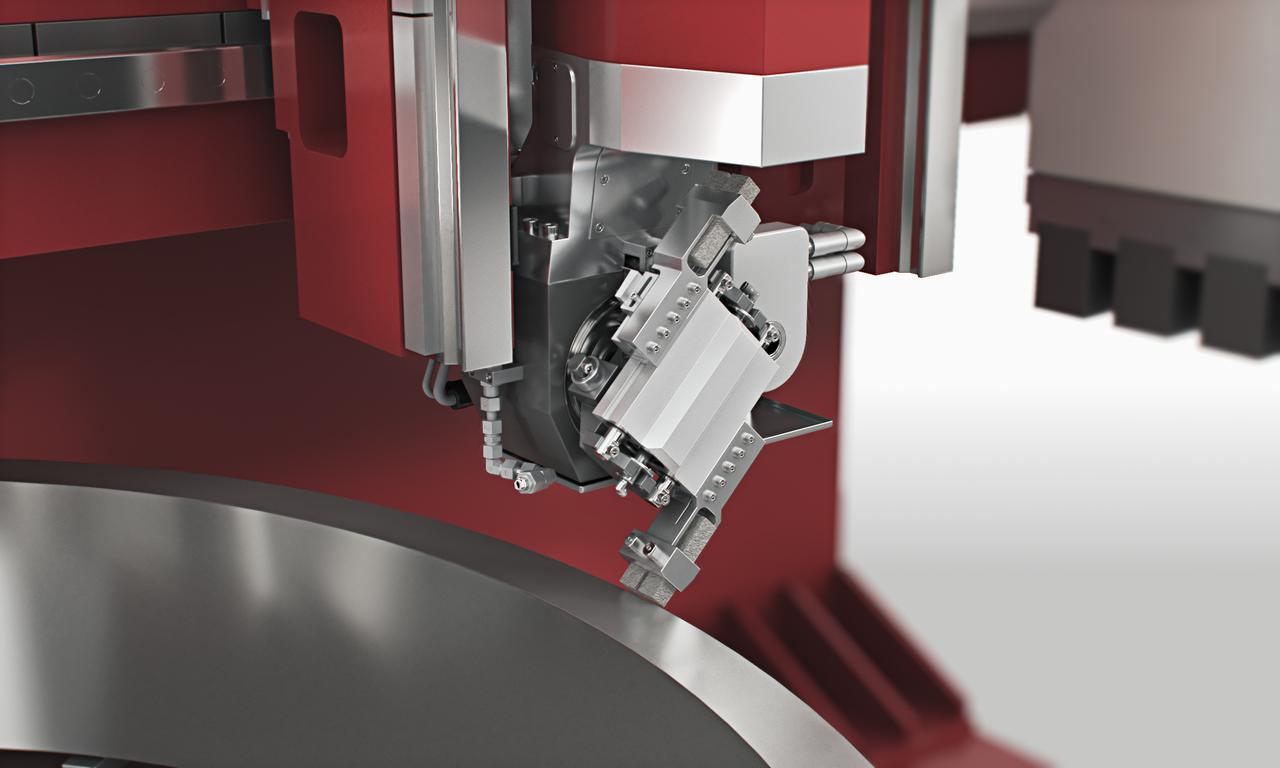

High Precision Hard Turning

Hard turning is used to machine components with hardness above 45 HRC, replacing or reducing grinding operations.

Our platforms are engineered to guarantee dimensional stability, low surface roughness, and minimal tool wear on hardened steels.

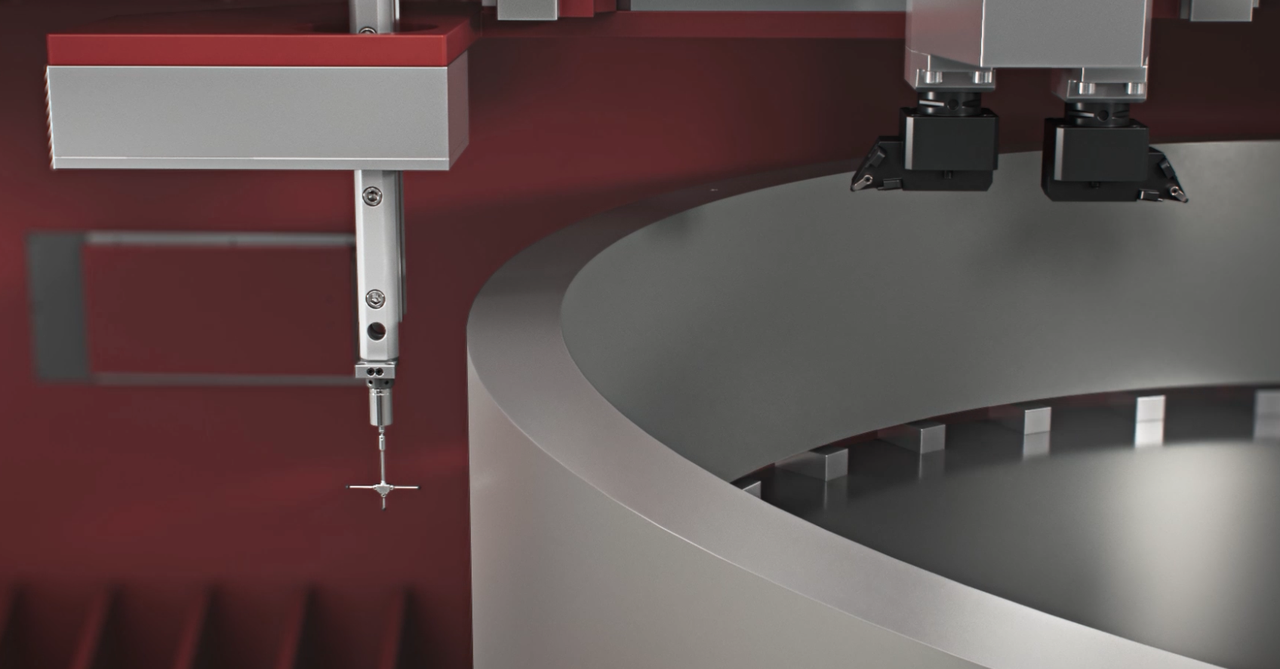

Superfinishing

Superfinishing is a process applied to improve surface quality after hard turning.

Our machines integrate stone or tape units with controlled pressure, oscillation and adaptive cycles.

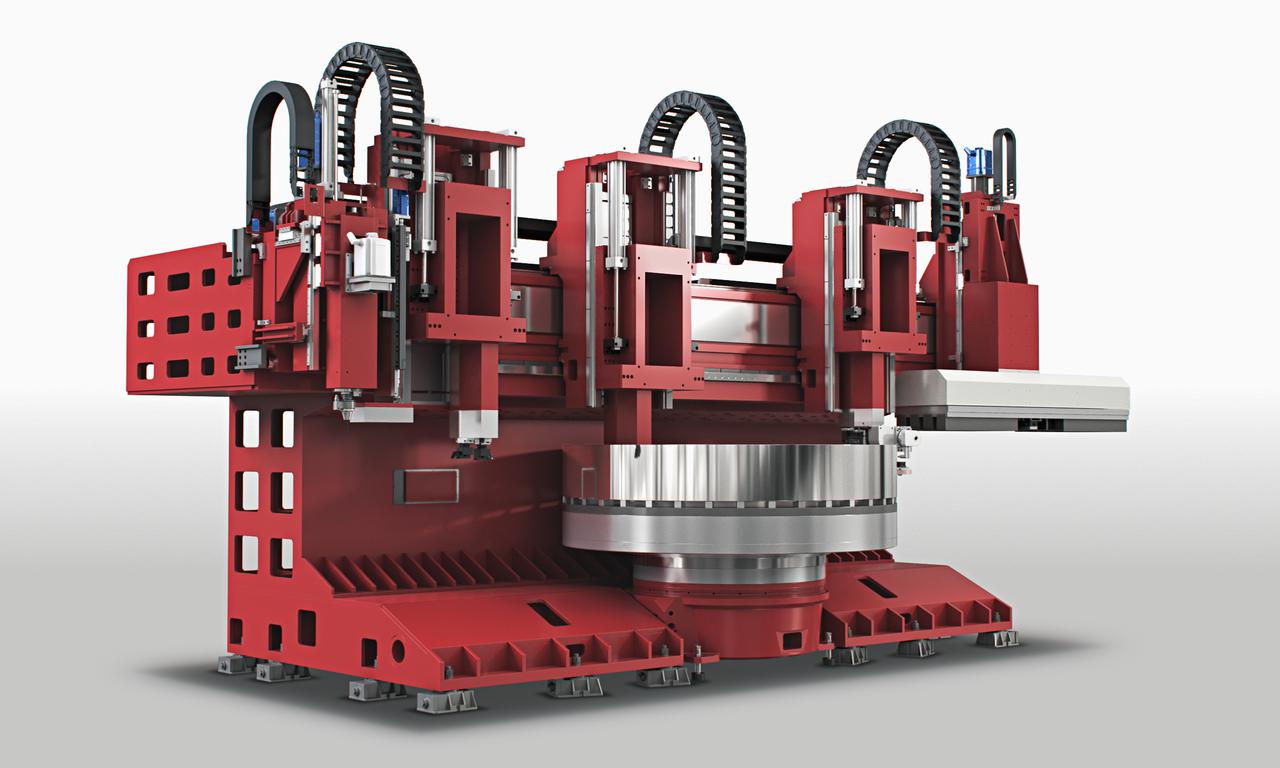

Combined Hard Turning + Superfinishing

Combined machines integrate hard turning and superfinishing on a single platform, eliminating the need for part transfer and re-clamping between operations.

This configuration enhances overall process stability.

Accuracy: ±10 µm or more

Surface Finishing: Ra ~0.8–1.6 µm

Suitable Materials: Soft to medium-hard materials

Tooling: Carbide inserts

Use case: General turning

Machine Rigidity: Medium

Termal Stability: Basic

Accuracy: ±0.5 µm or better

Surface Finishing: Ra ~0.01–0.1 µm

Suitable Materials: Hardened steels, often post-turning

Tooling: Abrasive stones or bonded abrasive tools

Use case: Final finishing for optimal surface and geometry

Machine Rigidity: Extremely high

Termal Stability: Highly controlled

Accuracy: ±1 µm

Surface Finishing: Ra ~0.1–0.3 µm

Suitable Materials: Hardened steels (45–65 HRC)

Tooling: CBN inserts

Use case: Grinding replacement ultra-precision

Machine Rigidity: Very high

Termal Stability: Advanced